Drive-in racking is ideal for storing large quantities of the same type of goods: your existing space can be used up to 90% more effectively with Drive-in racking compared to standard, conventional pallet storage systems.

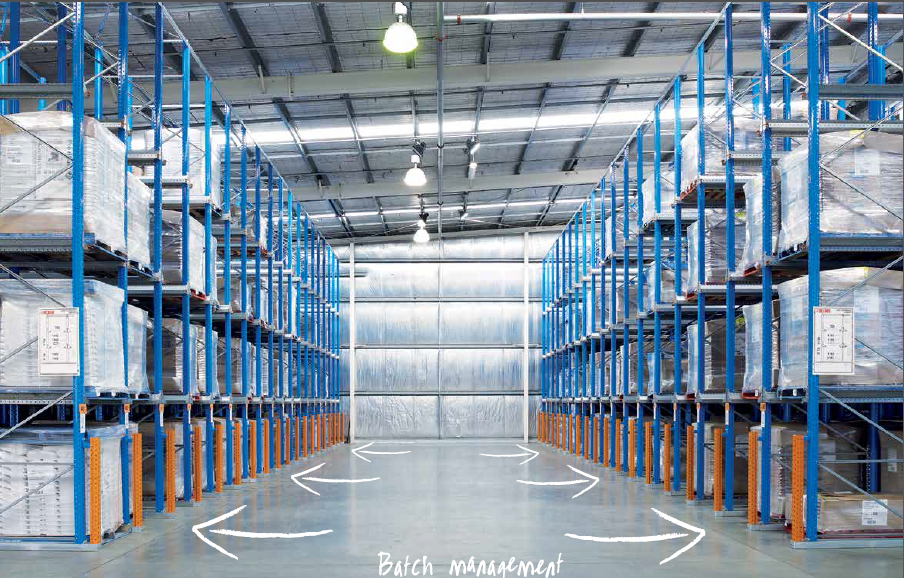

Drive-in racking is suitable for goods that can be stored on pallets behind or on top of each other, but ideal when greater access is required compared to block stacking. Pallets are stacked by the first-in, last-out (FILO) principle on supports mounted on both sides of the drive-in channels. This means that individual pallets cannot be accessed directly, but one by one from the front of the rack.

As a form of block stacking, drive-in racking systems significantly increase the storage density in a warehouse. Consequently, the existing space can be used up to 90% more effectively than with conventional pallet storage systems.

Drive-in racking eliminates the need for loading and picking aisles. The lift truck positions pallets on front-to-back rails, allowing rows to be stacked next to each other. Dexion drive-in racking provides a safe and efficient equivalent of block stacking for loads which are too fragile or unstable to be stacked on top of each other.

Benefits of Drive-in Racking

- High density storage – maximising cubic space

• More pallets stored per cubic metre than any other storage system

• Limited stock rotation – particularly suitable for seasonal goods

• Ideal for cold and chill storage applications

• Accessible by the First-In, Last-Out principle

• Used for bulk goods of the same type